VIP member

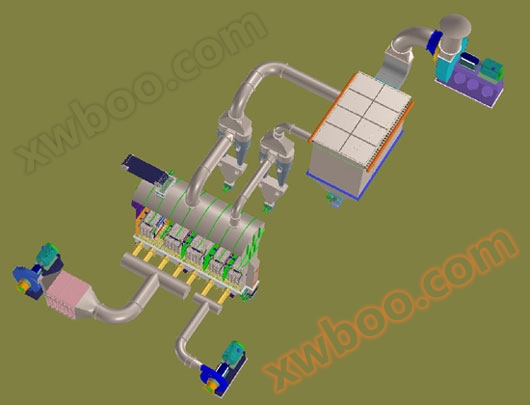

Polyacrylate ester, polycarbonate, polypropylene special dryer

The wet materials entering the fluidized bed of specialized dryers for polyacrylic esters, polycarbonate, and polypropylene come into contact with hot

Product details

principle

The wet material entering the fluidized bed comes into contact with the hot air above the air distribution plate, and the material particles are suspended in the airflow, forming fluidization. The tubular heat exchanger is immersed in the fluidized material, and steam is passed through the heat exchange tubes. The heat required for material dehydration is provided by both the tubular heat exchanger and the hot air used for fluidization. The dried finished product is discharged from the discharge port of the fluidized bed, and the dust containing gas is purified by the dust collection device and discharged into the atmosphere by the induced draft fan.

Energy saving and efficient. Due to the fact that most of the heat is provided by the built-in heat exchanger with a heat exchange efficiency of about 90%, the hot air is mainly used as

The power medium that ensures normal fluidization greatly reduces the amount of hot air required compared to conventional fluidized bed dryers. Therefore, its system power consumption and emissions

The gas and heat losses are correspondingly reduced, resulting in high drying efficiency.

Small footprint and low system investment.

Due to the lower operating gas ratio of the internal heating fluidized bed system compared to conventional fluidized beds, it can effectively reduce material entrainment and settling losses in the fluidized bed, thereby reducing the load on the dust removal system and alleviating environmental pressure.

Using special air distribution boards can prevent material leakage.

Scope of Application

This equipment is suitable for: refined salt, ammonium chloride, granular fertilizer, potassium carbonate, potassium chlorate, potassium phosphate, potassium chloride, potassium tartrate, calcium formate, calcium chloride, potassium nitrateABSDrying of various materials including plastics, acrylonitrile, butadiene, soda ash, adipic acid, sodium percarbonate, nitrate, polystyrene, ammonium nitrate, ammonium sulfate, calcium gluconate, vitamins, urea, titanium dioxide, terephthalic acid, tartaric acid, sewage sludge, sodium bicarbonate, sodium bromide, sodium carbonate, sodium chloride, sodium formate, soybeans, soy products, starch, ethylene, propylene, steel shavings, polyvinyl chloride, hydroquinone, calcium hypochlorite, calcium sulfate, cellulose derivatives, citric acid, copper sulfate, crystalline sugar, diammonium phosphate, heavy ash, etc.

Technical Specifications

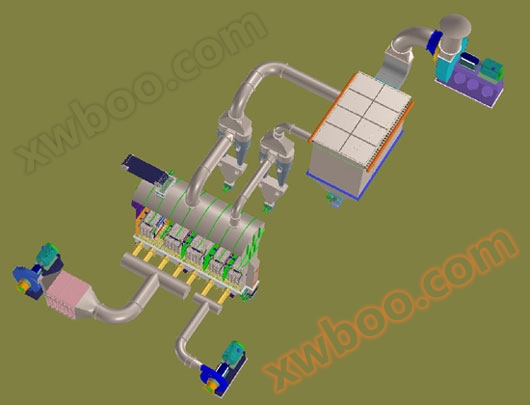

The wet material entering the fluidized bed comes into contact with the hot air above the air distribution plate, and the material particles are suspended in the airflow, forming fluidization. The tubular heat exchanger is immersed in the fluidized material, and steam is passed through the heat exchange tubes. The heat required for material dehydration is provided by both the tubular heat exchanger and the hot air used for fluidization. The dried finished product is discharged from the discharge port of the fluidized bed, and the dust containing gas is purified by the dust collection device and discharged into the atmosphere by the induced draft fan.

Energy saving and efficient. Due to the fact that most of the heat is provided by the built-in heat exchanger with a heat exchange efficiency of about 90%, the hot air is mainly used as

The power medium that ensures normal fluidization greatly reduces the amount of hot air required compared to conventional fluidized bed dryers. Therefore, its system power consumption and emissions

The gas and heat losses are correspondingly reduced, resulting in high drying efficiency.

Small footprint and low system investment.

Due to the lower operating gas ratio of the internal heating fluidized bed system compared to conventional fluidized beds, it can effectively reduce material entrainment and settling losses in the fluidized bed, thereby reducing the load on the dust removal system and alleviating environmental pressure.

Using special air distribution boards can prevent material leakage.

Scope of Application

This equipment is suitable for: refined salt, ammonium chloride, granular fertilizer, potassium carbonate, potassium chlorate, potassium phosphate, potassium chloride, potassium tartrate, calcium formate, calcium chloride, potassium nitrateABSDrying of various materials including plastics, acrylonitrile, butadiene, soda ash, adipic acid, sodium percarbonate, nitrate, polystyrene, ammonium nitrate, ammonium sulfate, calcium gluconate, vitamins, urea, titanium dioxide, terephthalic acid, tartaric acid, sewage sludge, sodium bicarbonate, sodium bromide, sodium carbonate, sodium chloride, sodium formate, soybeans, soy products, starch, ethylene, propylene, steel shavings, polyvinyl chloride, hydroquinone, calcium hypochlorite, calcium sulfate, cellulose derivatives, citric acid, copper sulfate, crystalline sugar, diammonium phosphate, heavy ash, etc.

Technical Specifications

|

Specification Model

|

production capacity

|

Dehydration ability

|

Initial moisture content

|

Final moisture content

|

|

NRLG20

|

20

|

4000

|

15~20

|

≤0.1

|

|

NRLG30

|

30

|

6000

|

15~20

|

≤0.1

|

|

NRLG40

|

40

|

8000

|

15~20

|

≤0.1

|

|

NRLG50

|

50

|

10000

|

15~20

|

≤0.1

|

|

NRLG70

|

70

|

14400

|

15~20

|

≤0.1

|

|

NRLG80

|

80

|

16400

|

15~20

|

≤0.1

|

|

NRLG90

|

90

|

18400

|

15~20

|

≤0.1

|

Online inquiry